Description

MAXREST is a one-component structural repair mortar, made of special cements, additives and selected aggregates, which provides a thixotropic product with quick-setting time that does not shrink. It firmly adheres to the surface which it is applied on, restores concrete to its original condition.

APPLICATION FIELDS

- For general repair and restoration work on structural concrete. Repairs honeycombs, cracks and fissures.

- Patching and protective covering of reinforcing rods affected by corrosion.

- To repair lintels, ran, water tanks and to restore architectural concrete permanently exposed to climatic conditions.

- Sealing of construction joints prior to waterproofing works in tanks, swimming pools, basements, etc.

- For restoration of lines and shapes of damaged pre-fabricated concrete elements.

ADVANTAGES

- Its quick-setting time, from 15 to 20 minutes, allows for an fast repair process.

- It forms part of the substrate and repairs are structurally sound, with properties comparable or higher than concrete.

- DOES NOT slump or needs form work.

- It does not shrink or cracks when setting.

- Odour-free and non-toxic, making it the ideal material to use in badly ventilated places, such as water tanks, shafts, sewers, etc.

- Does not contain any chloride.

- Only needs the addition of water for mixing.

APPLICATION INSTRUCTIONS

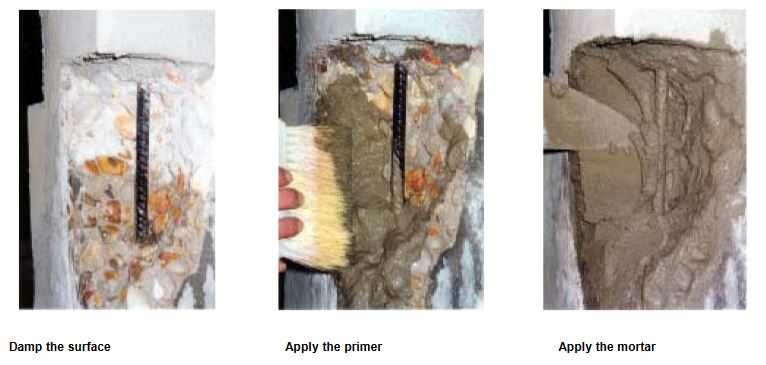

Surface Preparation

Surface should be clean and free of dirt, grease and loose particles. Remove all damaged and unsound concrete to expose a structurally sound substrate.

Expose all reinforcement affected by rust. Remove concrete all around the bars for an efficient cleaning and to surround it with a minimum thickness of at least 1 cm of MAXREST.

Eliminate rust by wire brush, needle gun, sand or shot blasting, etc. Apply sl ur r y coat of Maxr set or oxide converter MAXREST PASSlVE (Technical Bulletin nº 12). After cleaning, wash the concrete with water. Before applying MAXREST, wet the surface but do not leave free-standing water.

Mixing

A 25 kg bag of MAXREST is mixed with between 3,5 to 4,0 litres of clean water, depending on the ambient conditions and the consistency required, either manually or mechanically by low speed drill (400 – 600 r.p.m).

MAXREST takes fifteen to twenty minutes to set, depending on the temperature.

Mix only the amount of MAXREST that can be applied within eight to ten minutes.

Application

For an optimum bond, prepare a slurry mixing 5 parts of MAXREST with 1 part of water, mixing well until achieving a homogeneous consistency without any lumps. Apply the slurry using a MAXBRUSH type brush on the surface to be repaired and on the reinforcement bars, filling all voids and pores, allowing 5 to 8 minutes before continuing the repair.

While the slurry is still fresh, start placing MAXREST with its consistency of repair mortar.

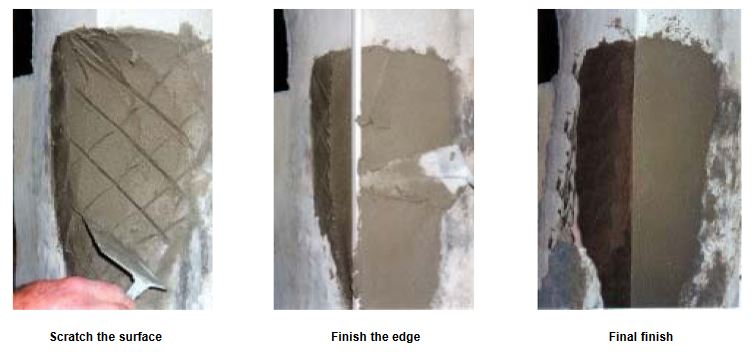

Apply in successive layers between 2,5 and 3 cm, scratching the surface with the trowel to make the next layer adheres firmly.

Between layers, wait 10 to 15 minutes depending on temperature. If the different layers become warm, wet the surface with cold water.

Application Conditions

Do not apply at temperatures below 5 ºC or if lower temperatures are expected during the 24 hours following the repair. Do not apply on frozen or frosted surfaces.

Curing

For better curing once the job is finished cover with wet cloth to protect from high temperature or direct hot sun.

Cleaning

Clean all tools and equipment immediately with water after use. Once MAXREST hardens it can only can be removed by mechanical methods.

CONSUMPTION

Estimated consumption of MAXREST approximately 1,67 kg/m2 per 1 mm thickness.

One kilogram of MAXREST will fill approximately 0,6 litres.

PACKAGING

MAXREST is supplied in 25 kilogram drums and bags, and 5 kilogram cans

STORAGE

IMPORTANT INDICATIONS

Do not use leftover mixed material to prepare a new batch

Do not add sand, aggregates or cement to increase volume

Do not use high speed mixers

Do not mix for prolonged periods.

Do not apply on painted or structurally weak surfaces.

Do not apply in layers exceeding 3 cm thickness

Do not allow the layers to heat up; Mist spray with water if required.

Setting time is measured at 20 ºC. Higher temperatures reduce the setting time and lower temperatures delay the setting time.

With low temperatures keep the product in a warm place and use lukewarm water to accelerate the setting time.

With hot temperatures keep the product in a cool place and use fresh clean water for the mix. Wet the differentlayers. Mix small batches of material and apply immediately.

For further information consult our Department.

SAFETY AND HEALTH

MAXREST is non-toxic but as all cementitious product it is an abrasive compound. Rubber gloves and safety goggles must be used to mix and apply the mixture.

In case of skin contact, wash affected areas with soap and water. In case of eye contact, rinse with clean water but do not rub. If irritation continues, seek medical attention.

Safety Data Sheet of MAXREST is available by request.

Disposal of the product and empty packaging must be carried out according to national regulations by the final user.

TECHNICAL DATA

| Appearance and colour | Grey powder |

| Apparent density in powder (kg/cm3) | 1,045 ± 0,05 |

| Mixing water (% in weight / weight prod.) | 15 ± 1 |

| Pot life (minutes, 20 ºC) | 15 |

| Apparent dry density (kg/cm3) | 1,98 ± 0,05 |

| Adhesion on concrete (MPa) | 1,8 |

Setting (minutes 20 ºC) Beginning Final |

20 25 |

Flexotraction strength (MPa) 7 days 28 days |

5,0 7,7 |

Compressive strength (MPa) 7 days 28 days |

29,0 45,5 |

| Capilarity (c) (g /dm2 min1/2) | 1,24 |

| Elasticity modulus (MPa) | 21.000 |

Additional information

| Pail | 5kg, 25kg |

|---|

You may also like...

-

MaxPlug

- Drizoro Products

- This product has multiple variants. The options may be chosen on the product page