Description

MAXGROUT® is an one-component non-shrink mortar formulated from special cements and well-graded mineral products which provides high mechanical properties and fluidity. Contains no chlorides or metal particles. It comes in powder form, ready to use mixing only with water.

APPLICATION FIELDS

- Anchoring of pillars in concrete prefabricated structures.

- Filling of steel column bases. Beam support in bridges. Anchoring of bolts, cables, etc.

- Filling of machinery foundation between concrete and steel plates.

- Structural repair and strengthening of damaged or weak concrete structures such as foundations, beams, pillars, etc.

- Repairing joints in pavements.

- Void-filling corrective process and consolidation under concrete slabs.

ADVANTAGES

- High early and ultimate strength.

- Very good adhesion on surfaces, it becomes structural part of the substrate and it withstands to repeated loads.

- Non-shrink and slightly expansive, thus it does not lose contact with the substrate where is placed.

- High cohesion of the fresh mortar without segregation or bleeding.

- Waterproof, fireproof and non-toxic.

- Unaffected by extreme temperatures once set.

- Contains no chlorides or metal particles, it is non-corrosive for steel surfaces.

- Resistant to water, oil and grease.

APPLICATION INSTRUCTIONS

Surface preparation

The surface must be structurally resistant and clean, free of dust, coatings, efflorescences, oil, demoulding agents, gypsum or any other foreign material. In order to clean the surface high water pressure cleaning or sand-blasting is recommended. All steel and reinforcements must be thoroughly cleaned.

Before the application of MAXGROUT®, the surface must be saturated with clean water, but do not leave free-standing water.

On porous substrates, or on the contrary for very smooth surfaces, a bonding agent such as MAXBOND® (Technical Bulletin nº: 10) should be applied.

Mixing

Pour MAXGROUT® into a clean drum containing part of the water and then start the mixing in order to break up any lumps. Use 3 to 3,5 litres of water per 25 kg bag depending on the required consistency (12% and 14% by weight). Mixing is best done by mechanical means such a slow speed mixing drill (400 – 600 rpm). The mixture should be mixed for 3 to 4 minutes, avoiding to introduce air bubbles into the mix. A concrete mixer can be also used. If product is mixed by hand, increase the mixing time until all lumps disappear. Do not use more water than the recommended ratio.

Allow to rest for 2 to 3 minutes so any introduced air bubbles during mixing can disappear. Place MAXGROUT® within the following 15 – 20 minutes.

For volumes greater than about 0,1 m3 or thickness greater than 4 cm, a mixture adding 8 kg of dry and clean sand with size from 3 to

5 mm per each 25 kg bag of MAXGROUT® should be done. Mix all together with 2,75 to

3 l of water per bag, depending on the required consistency, but avoid any bleeding or segregation by an excess of water.

Placing

MAXGROUT® is placed simply pouring by gravity directly from the mixing container. In order to avoid cold joints and minimize the chance of air entrapment, MAXGROUT® should be placed in a continuously way and also in one direction from one side to the other. If it is necessary, a manual vibration element can be used in order to help to fill the volume but an excessive vibration must be avoided as possible because it may cause bleeding and air entrapment. If it is necessary, machine pumping applications are also possible. Air vents should be provided to facilitate the exit of air from the space to be filled.

Use small mould supplements around placing area in order to help to pouring procedure if they are required.

Application conditions

The optimum application temperature range is from 10 to 25 °C.

In winter, do not apply MAXGROUT® when ambient or application surface temperature is below 5 °C or if such temperatures are expected within the 24 hours after placing. Do not apply the grout on frozen or frosted surfaces.

For applications during hot temperatures and windy conditions, i.e. summer time, it is recommended to use iced or cold water and store MAXGROUT® in a cool place. Cooling the base plate with cold water is also advisable with such conditions.

Curing

Curing procedures should begin inmediately after placement. Provide a moist curing by fogging or protecting the area with wet burlap or rags covered with plastic sheeting. A quality curing compound such as MAXCURE® (Technical Bulletin nº: 49) can also be used. These curing procedures should be observed mainly with high temperature and wind or low humidity conditions.

Cleaning

All tools and equipments must be cleaned inmediately with water after use. Once the grout sets can only be removed by mechanical methods.

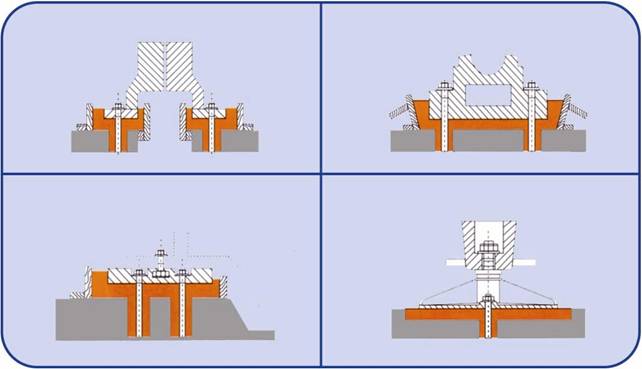

Different methods for placing and filling with MAXGROUT®

Application conditions

The optimum application temperature range is from 10 to 25 ºC.

In winter, do not apply MAXGROUT when ambient or application surface temperature is below 5 ºC or if such temperatures are expected within the 24 hours after application. Do not apply the grout on frozen or frosted surfaces.

For applications during extreme hot temperatures and windy conditions, it is recommended to use iced or cold water for mixing and store MAXGROUT in a cool place. Cooling the base plate with cold water is also advisable.

Curing

Curing procedures should begin immediately after placement. Provide a moist curing by fogging or protecting the area with wet burlap or rags covered with plastic sheeting. A quality curing compound such as MAXCURE (Technical Bulletin nº 49) can also be used. These curing procedures should be observed mainly with high temperature and wind or in low humidity conditions.

Cleaning

Clean all tools and equipment immediately with water after use. Once the grout sets it can only be removed by mechanical methods.

CONSUMPTION

Pure product application: A 25 kg bag of MAXGROUT® fills a volume from about 12,5 to 13,5 litres, depending on the mixing water

(0.5 – 0.54 l/kg). Approximately 2 kg of MAXGROUT® per square meter and mm of thickness.

Mixture application: A mixture consisting of 8 kg of sand per 25 kg bag of MAXGROUT® fills a volume from about 16,25 to 17 litres, depending on the mixing water (0,65 – 0,68 l/kg). Approximately 1,4 kg of MAXGROUT® per square meter and mm of thickness.

IMPORTANT INDICATIONS

Do not use more water for mixing than the ratio recommended.

Do not add cement or other not specified compound to MAXGROUT®.

Do not use MAXGROUT® for levelling and finishing of pavements.

For further information, consult our Technical Department.

PACKAGING

STORAGE

SAFETY AND HEALTH

As all cementitious products, MAXGROUT® is non-toxic but it is an abrasive compound. Both protective rubber gloves and safety goggles must be used to prepare and apply the mixture. In case of skin contact, wash the affected areas with soap and water. In case of eye contact, rinse thoroughly with clean water but do not rub. If iriitation continues, seek medical attention.

For further information, Safety Data Sheet for MAXGROUT® is available by request.

Disposal of the product and its empty packaging must be made according to official regulations. This disposal must be made by the final user.

TECHNICAL DATA

| Properties of powder product | |||

| Colour and appearance | Grey powder | ||

| Aggregate size (mm) | 0 – 3 | ||

| Powder apparent density (g/cm³) | 1,30 ± 0,05 | ||

| Properties of fresh product | |||

| Mixing water/ product weight (%) | 12 – 14 | ||

| Setting-time (hours, at 20 ºC) | 5 – 6 | ||

| Slump, vibrating table (mm) | 209 (12%) | >300 (14%) | |

| Segregation | None | ||

| Properties of hardened product | |||

| Dry density (g/cm³) | 2,25 ± 0,05 | ||

|

Compressive strength (MPa) 24 hours 3 days 7 days 28 days |

Mixed with 12% of water |

Mixed with 14% of water |

|

| 29,9 57,8 68,3 89,2 | 19,3 51,0 60,8 78,5 | ||

| Flexural strength (MPa) 24 hours 3 days 7 days 28 days |

5,75 7,20 11,55 14,42 |

3,90 5,95 8,50 10,20 |

|

| Elasticity modulus (MPa) | > 4·104 | ||

| Adhesion on concrete (MPa) | > 2,5 | ||

| Adhesion on steel reinforcement (MPa) | > 2,5 | ||

| Expansion (%) | 0,05 | ||

You may also like...

-

MaxRest

- Drizoro Products

- This product has multiple variants. The options may be chosen on the product page

-

MaxPlug

- Drizoro Products

- This product has multiple variants. The options may be chosen on the product page