Description

APPLICATION FIELDS

- Fixing of low porosity or non-poroustiles, vitrified tile, glass mosaics, porcelain, marble, natural stone, etc. for indoor or outdoor use, on floors and walls.

- Tiling of ceramic tiles on substrates subject to movement ssuch as facades, under floor heating systems, roofs, timber, plastic, etc.

- Tiling on substrates subject to water immersion such as swimming pools,fountains, water tanks, etc.

ADVANTAGES

- Very high adhesion on non-porous substrates and with good mechanical performance.

- Good flexibility, absorbing movements from substrate due to shrinkage processes, thermaldilatations, etc.

- Easy to use. Long open time.

- Excellent water retention, avoids dampen thesubstrate or tiles

APPLICATION INSTRUCTIONS

Surface preparation

Surfaces must be structurally sound, clean and free from dust, grease, paints, efflorescence, oils, demoulding agents, gypsum, loose concrete orany other material that could affect the adhesion of the product.

Substrate must be as flat as possible, with no unevenness greater than 5 mm measured with a 2meters long guide. Voids, non active-cracks and surface damages must be prepared by chipping or sandblasting up to 2 cm depth and repaired with a structural mortar such asMAXREST® or MAXRITE® 500(Technical Bulletins N.: 2 and 50, respectively). Observe a minimum curing time 24 hours before applying MAXKOLA® FLEX. Do not apply MAXKOLA® FLEX over dead, thin or delayed setting gypsum plasters.

Mixing

Mix preparation

Application

IMPORTANT INDICATIONS

Allow 28 days minimum curing for newconcrete and mortars.

Do not add cements, admixtures or aggregates that may affect the mortar properties.

Observe the recommended mixing water ratio.

Remix briefly the mortar in order to keep its workability, butdo not add more water.

Do not excess the maximum thickness recommended per layer of 6mm.

The ceramic tiles must be set within the open time of the mortar, before non adhesive skin is formed on the surface of the mortar.

Double spread application is preceptive for 35 x 35 cmceramic tiles or higher dimensions andin heavy pedestrian traffic and withpronounced relief.

For further information and other uses not specified in this Technical Bulletin, consult our Technical Department.

PACKAGING

STORAGE

SAFETY AND HEALTH

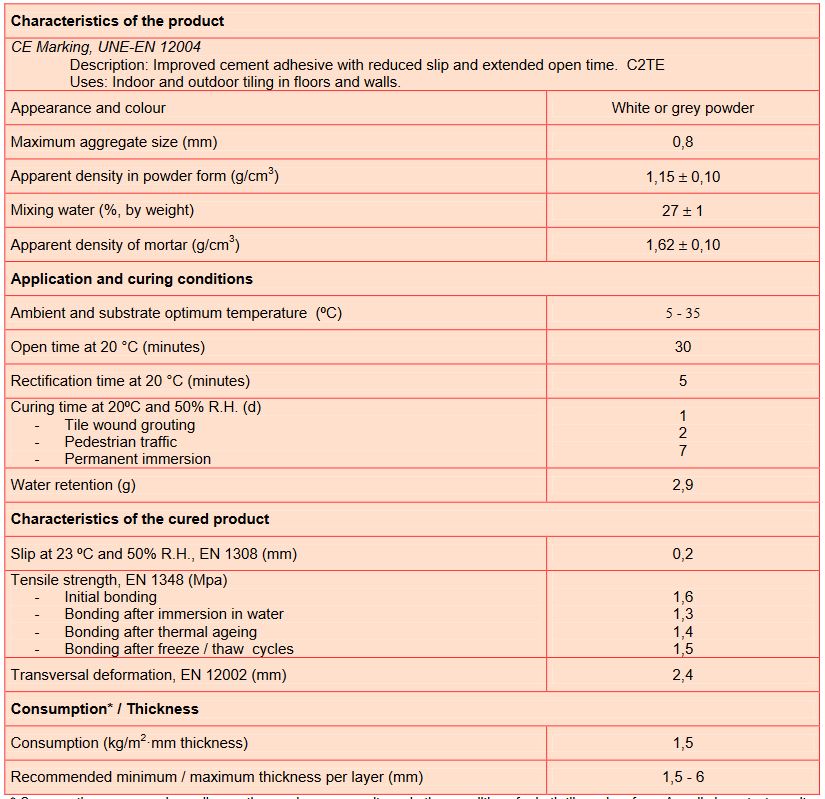

TECHNICAL DATA

Additional information

| Size | Unit, Pallet (48 bags) |

|---|

You may also like...

-

MaxRest

- Drizoro Products

- This product has multiple variants. The options may be chosen on the product page