Description

MAXJOINT® FLEX is a one-component, cementbased mortar formulated with selected aggregates and special additives that provides very high adhesion on building materials and high capacity to absorb substrate deformation. It is suitable for crack filling and pointing mortar on ceramic tiles, stone, brick, etc.

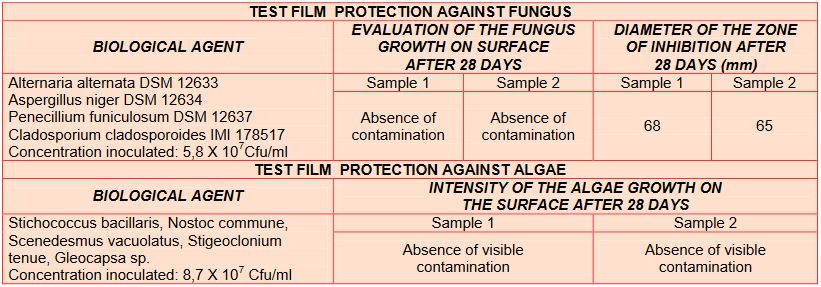

Also available the type MAXJOINT® FLEX POOL, with high microbiological resistance against the growth of algae and fungi on surface.

APPLICATION FIELDS

- It points joints in brick, stone, concrete block, and all types of masonry for outdoor and indoor applications.

- Pointing of tiles over substrates subject to movements such as facades, terraces, wood, floor heating systems, outdoor pavements, etc.

- Combined with MAXSEAL® FLEX or MAXKOLA® FLEX providing a full flexible system in swimming pools, water reservoirs, fountains, etc.

- Pointing in areas with environmental conditions favourable to bacterial reproduction such as swimming-pools, wastewater treatment plants, aquariums, hospitals, schools, laboratories, industries, etc.

- Applications exposed to a wide range of temperature or relative humidity.

ADVANTAGES

- Suitable for pointing all type of ceramic tile (glazed or unglazed), marble, porcelain mosaic, etc.

- High microbiological resistance type reduces the maintenance costs and provides healthy and safer conditions.

- Excellent bond strength on every surface.

- It waterproofs the joint from rain water.

- It hardens without stress and cracks on joints up to 20 mm width.

- Suitable for permanent immersion.

- Excellent colour stability.

- Available in several colours under request.

- Easy to use and to clean.

APPLICATION INSTRUCTIONS

Surface preparation

Allow 24 – 48 hours of curing for bonding mortars after tiling and before applying MAXJOINT® FLEX.

In new tiling jobs set suitable size plastic spreaders in order to maintain the right tile wound.

Remove all excess of bonding mortar in the joints. The joints must be free of dust, grease, and loose particles of the bonding mortar, or any other dirtiness that may affect the adherence of the product. Clean all joints with water-pressure. Prior to application dampen the surface but do not leave any puddles of water in the joint. All expansion joint must be treated with a suitable MAXFLEX® sealant.

Mixing

MAXJOINT® FLEX is mixed with 4,75 a 5,75 (19 – 21%) litres of clean potable water. Add the required amount of clean water in a clean container, according to the ambient conditions and the desired consistency and pour slowly MAXJOINT® FLEX. Mix either manually or mechanically by a low speed drill (400 – 600 rpm) until achieve a homogeneous mixture and lumpfree. Allow the mix to rest for 4 – 5 minutes and re-mix briefly before application.

Prepare the quantity of MAXJOINT® FLEX that can be applied in one hour. After 30 minutes, can be mixed again the mixture in order to keep the workability of the mortar but do not add more water.

Application

Use a trowel or rubber float to spread and press into the joints until they are completely full. For the pointing tiles in ceramic or porous brick is advisable to use a caulking gun for placement of mixture into the joint avowing the risk of stain the tiles. Before the initial setting-time of MAXJOINT® FLEX, when the mortar start getting matt, use a tuck-pointing trowel in order to get a smooth finish of the surface.

Application conditions

Do not apply if rain is expected within the first 24 hours.

Do not apply with substrate and/or ambient temperature is at or below 5°C, or when temperatures are expected to fall below 5 °C within 24 hours. Do not apply to frozen or frostcovered surfaces.

For applications at hot temperatures (> 35 ºC), low relative humidity, direct sunlight and/or windy conditions, surface must be wet thoroughly with plenty of water prior to application.

Protect from high temperatures (> 35 ºC), moderate to high winds, low humidity conditions or direct sunlight exposure, i.e. in summer time.

Damp the substrate with water.

Curing

Prevent rapid drying of MAXJOINT® FLEX and protect from extreme heat and direct sunlight, keeping its moisture for at least 24 hours after application, spraying a fine mist of water, without causing the washing out, or by using polyethylene sheeting, damp burlaps, etc.

Allow MAXJOINT® FLEX to cure for at least 1 day at 20 ºC and 50% for pedestrian traffic and 7 days before water immersion or flooding test.

Lower temperatures and/or higher R.H. values increase the curing time.

Cleaning

Clean with a wet sponge or cloth while mortar is still fresh to remove any excess mortar from the joint or face of the tile. All tools and equipments can be clean with water immediately after application. Once MAXJOINT® FLEX hardens is removed only by mechanical means.

MAXJOINT® FLEX black colour, after 5 – 7 curing days, will require a washing with water pressure to remove any possible stain of black loose particles.

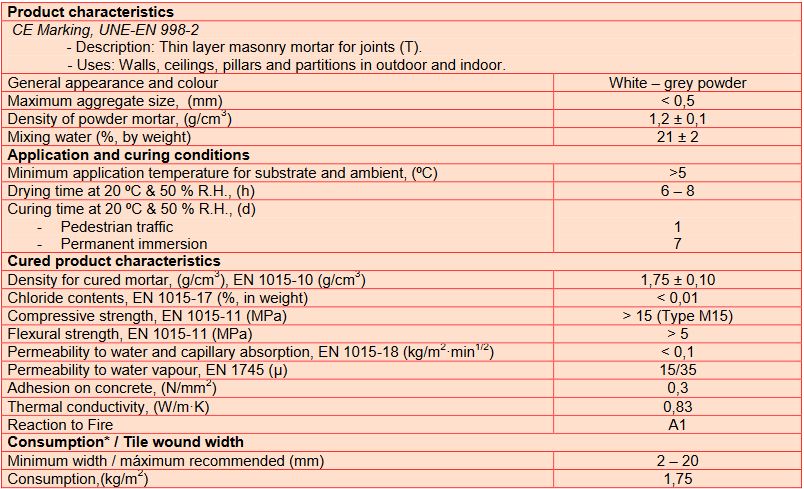

CONSUMPTION

One kilogram of MAXJOINT® FLEX fills approximately 0.6 litres.

Estimated consumption, depends on the tile size and tile wound or joint, it may be calculated with the following formulae;

Consumption:

- Consumption (kg/m2): ((A+B) / (A*B)) * C * D *1,75

A: Tile width (mm), B: Tile length (mm), C: Tile wound depth, and D: width of the tile wound (mm).

So for a surface coating with 20 x 20 ceramic tiles with 10 mm of tile wound width and 10 mm tile wound depth the consumption of MAXJOINT® FLEX is 1,75 kg/m2.

These values are for guidance only and may vary depending on porosity, texture, substrate conditions and application method. Perform a preliminary test on-site to ascertain the total consumption exactly.

IMPORTANT INDICATIONS

Do not add cements, additives, aggregates or other compounds.

Use the recommended mixing water to powder ratio.

Do not use leftovers from previous mixes.

To restore the workability, remix the mortar but never add more water.

PACKAGING

MAXJOINT® FLEX and MAXJOINT® FLEX POOL are supplied in 25 kg bags, in white and grey colour.

Other special colours as black, cream, blue, jade, brown, beige, terracotta and salmon, under special request.

STORAGE

Twelve months in its original unopened packaging, in a dry and covered place, protected MAXJOINT ®FLEX from direct sunlight, frost and humidity, with temperatures above 5ºC.

SAFETY AND HEALTH

MAXJOINT® FLEX is non-toxic but it is an abrasive compound. Protective rubber gloves and safety goggles must be used during application. In case of eye contact rinse thoroughly with clean water, but do not rub. In case of skin contact clean with soap and clean water. If irritation continues, seek medical attention.

For further information Safety Data Sheet of MAXJOINT® FLEX is available by request.

Disposal of the product and its empty packaging must be made by the final user and according to official regulations.s

Also available the type MAXJOINT® FLEX POOL, with high microbiological resistance against the growth of algae and fungi on surface.

TECHNICAL DATA

Consumption may vary depending on the roughness, porosity and other conditions for both tile and surface. A preliminary test on-site will determine the coverage exactly.

MICROBIOLOGICAL RESISTANCE

You may also like...

-

MaxRest

- Drizoro Products

- This product has multiple variants. The options may be chosen on the product page

-

MaxPlug

- Drizoro Products

- This product has multiple variants. The options may be chosen on the product page